Building a new future of injure monitoring

Efficient, reliable and non-invasive biosensing bandages

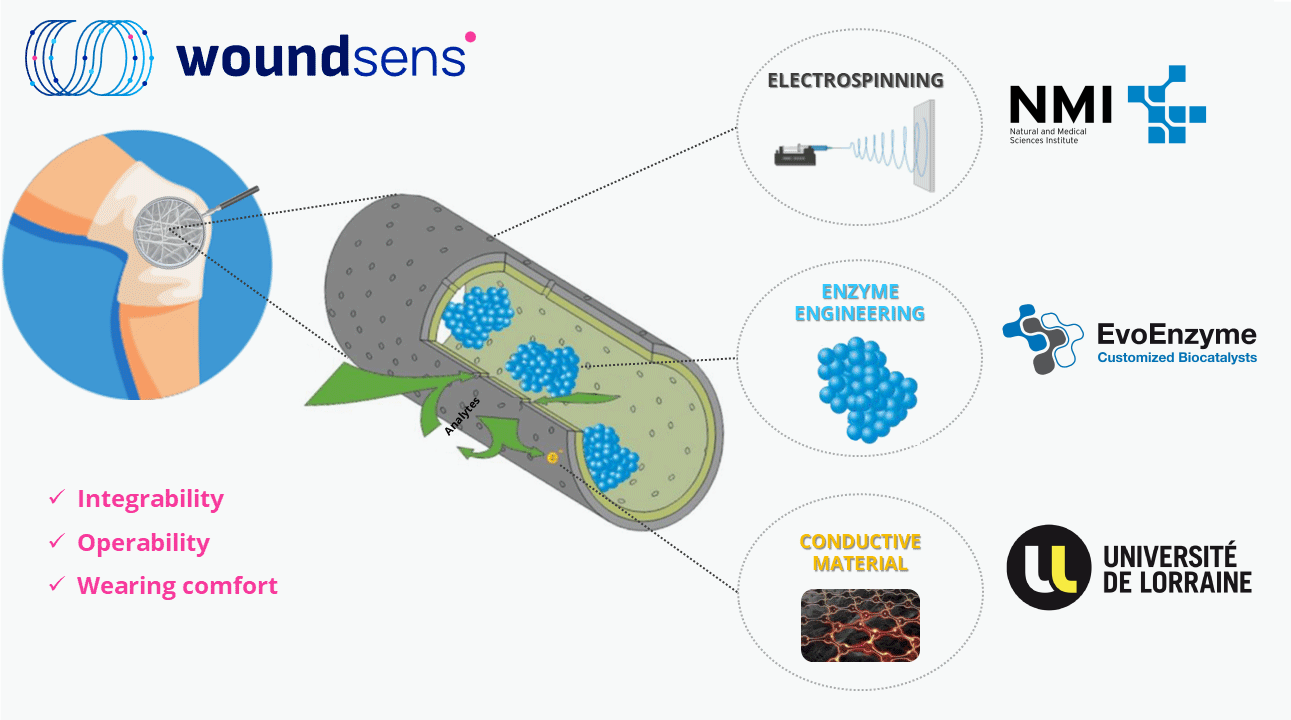

At WOUNDSENS, we are determined to change the narrative around chronic nonhealing wound care. We are working on three innovative strategies that will transform the way we design and manufacture smart wound dressings.

Simplifying manufacture

We aim to develop a one-step sensing element manufacture for wearable wound dressings, integrating sensor elements into the material to enhance wearing comfort and operability, and enable easy implementation into existing standard manufacturing processes.

Increasing sensitivity

Traditional methods of coating sensors on flat surfaces often result in the loss of important information. By developing a porous fiber-electrode combination that ensures comprehensive bio-catalytical signal conversion across the entire wound dressing surface, our sensors will show high sensitivity, enabling early detection of infections.

Ensuring versatility

Every wound is unique, so solutions should be tailored accordingly. The project’s approach utilizes versatile hollow fibers to adjust the wound’s micro-environment, allowing to control factors such as pH levels and solute concentrations to contain different biocatalysts. This adaptability ensures that the smart wound dressings can cater to a wide range of wound care needs.

The WOUNDSENS approach

Interconnecting innovation in three cutting-edge areas

Enzyme Engineering Module

Led by EvoEnzyme

This module is dedicated to adapt enzymes to the highly demanding manufacturing process and operational conditions of the biosensor. Our approach is harnessing advanced wet-lab and computational protein engineering methods, including directed evolution and ancestral resurrection, to tailor highly active and stable oxidoreductase enzymes with superior performance.

Through close collaboration and an interdisciplinary approach, WOUNDSENS aims to deliver a wearable biosensor that provides continuous, robust, and sensitive electrochemical detection on the wound’s microenvironment.

Conductive Material Module

Led by Université de Lorraine

This module aims to unlock the potential of carbon-based materials, particularly graphene, which have demonstrated promising applications in the fields of energy and environment. Université de Lorraine will focus on developing forefront processes to obtain high-quality conductive materials that fulfill the specific requirements of electrospinning. These requirements include precise particle dimensions and optimal electrical and catalytic properties to ensure exceptional conductivity and durability in various environments.

Electrospinning Module

Led by the NMI Natural and Medical Sciences Institute

Specializing in electrospinning, NMI excels in the precise fabrication of nanofibers from various materials. In this module, we harness the power of electrospinning to create hollow fibers as the fundamental building blocks of our biosensor. Electrospinning offers numerous advantages, including the entrapment of enzymes, fine-tuning of enzyme activity within the fibers, increased surface area, and integration of conductive materials for electrochemical detection. NMI will optimize the electrospinning process, ensuring the production of biocompatible, permeable fibers that allow for the analysis of wound analytes while maintaining enzyme integrity.

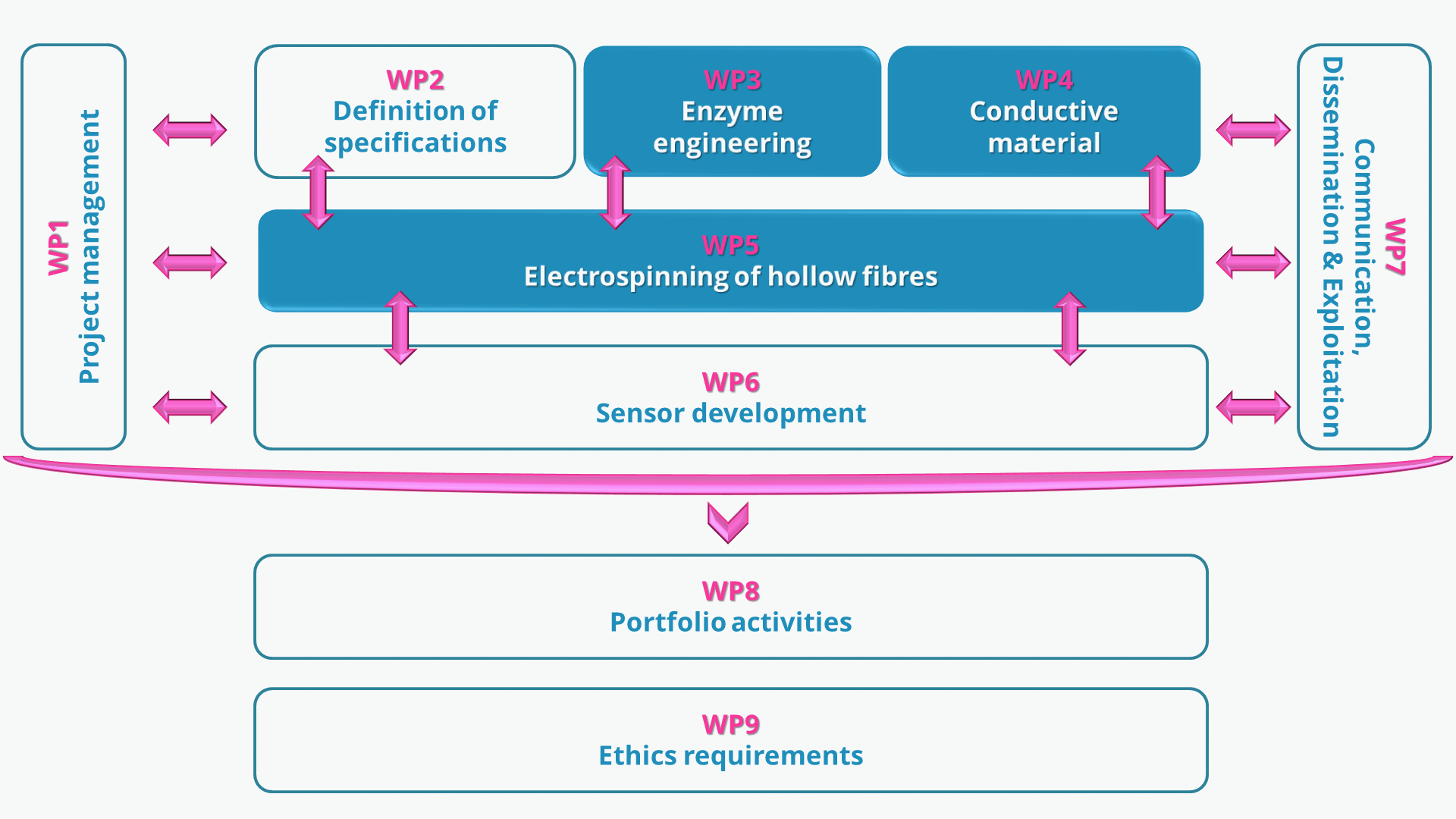

Our workplan

WOUNDSENS´ work plan is divided into 6 highly interactive work packages (WP):

WOUNDSENS will overcome diverse barriers for continuous wound care monitoring, since current methods of wound infection diagnosis involves traumatic bandage removal, take samples by invasive techniques or long times in microbiological analysis.

WOUNDSENS aims for a new approach towards noninvasive, long-term stable, and capable of in situ surveillance of wound biomarkers, facilitating compliance of patients to wound care continuum. WOUNDSENS will allow to set up alternatives on site visits including use of telemedicine and creation of videos to help with wound dressing changes among others and encouraging a do-it-yourself wound dressing protocol and use of homemade substitutions.