Electrospinning is a versatile method to create biomimetic fibrous structures with fiber diameters in the nano- and micrometer range. Many different polymer solutions can effectively be processed with this method when a strong electrical field is applied. The resulting endless nanofibers are collected as fiber mats.

Some of the relevant electrospinning parameters that influence fiber formation include:

- Charge density and viscosity of the polymer solution

- Flowspeed, tip-to-collector distance and electric potential

The resulting fiber diameter, but also the fiber alignment can be regulated with these parameters to achieve different product characteristics.

Potentials of electrospinning

Electrospinning can be used to process synthetic but also natural polymers to produce tissue-like elastic materials. These materials can be further functionalized, e.g., by coating with bioactive factors on the surface. Due to their mesh-like structure, electrospun materials have great potential for several applications, such as filtration purposes, biomedical engineering, drug delivery carrier or wound dressing. Especially for the latter, materials spun from natural polymers that mimic the human extracellular matrix, can support the formation of new healthy tissue, reducing scar formation.

Challenges

As many different parameters influence the process, it is sometimes challenging to achieve defined fiber and pore structures in a reproducible manner. Therefore, also environmental conditions such as humidity and temperature must be strictly controlled during the process. If biological substances like enzymes and proteins are used during electrospinning, they can even lose their functionality due to elevated temperature.

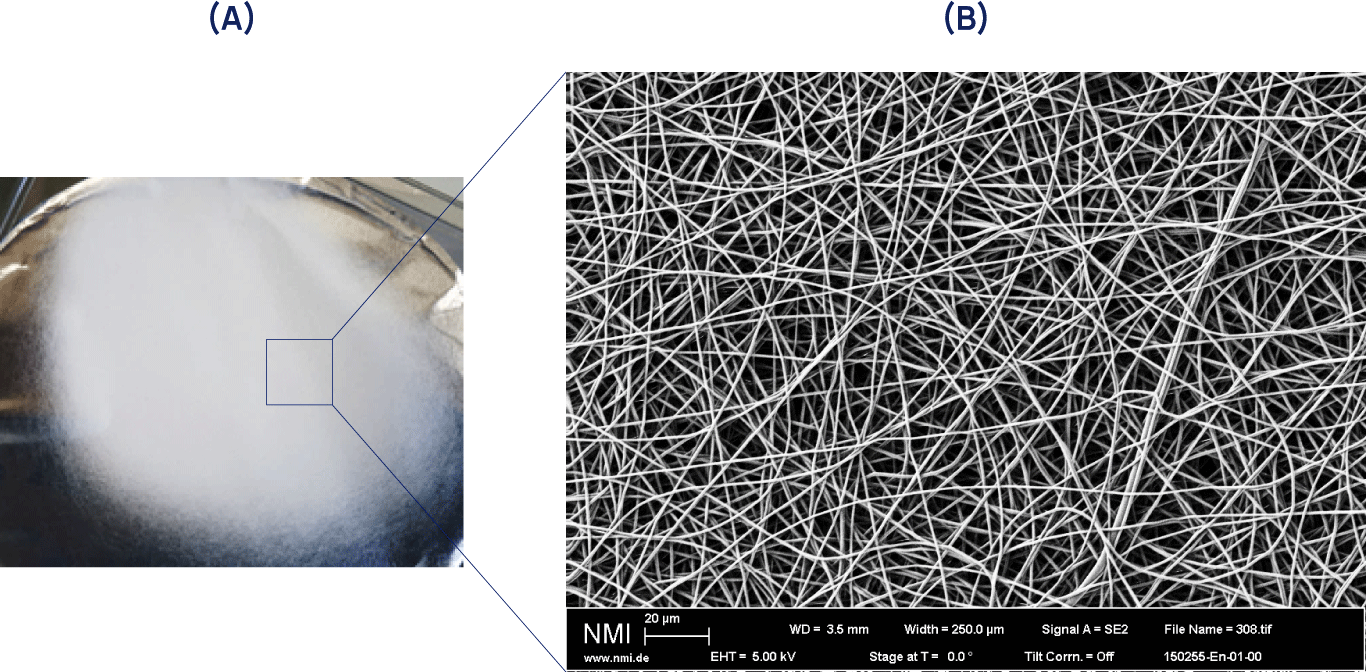

Electrospun fiber mat.

(A) Macroscopic view and (B) scanning electron microscopic magnification to visualize the single fibers (NMI, Reutlingen).

References:

- Visser, D., Bakhshi, H., Rogg, K., Fuhrmann, E., Wieland, F., Schenke-Layland, K., … & Hartmann, H. (2022). Green chemistry for biomimetic materials: Synthesis and electrospinning of high-molecular-weight polycarbonate-based nonisocyanate polyurethanes. ACS omega, 7(44), 39772-39781.

- Visser, D., Rogg, K., Fuhrmann, E., Marzi, J., Schenke-Layland, K., & Hartmann, H. (2023). Electrospinning of collagen: Enzymatic and spectroscopic analyses reveal solvent-independent disruption of the triple-helical structure. Journal of Materials Chemistry B, 11(10), 2207-2218.

- Islam, M. S., Ang, B. C., Andriyana, A., & Afifi, A. M. (2019). A review on fabrication of nanofibers via electrospinning and their applications. SN Applied Sciences, 1, 1-16.